Unboxing 100 Mask Orders | Relaxing ASMR Packaging

Table of Contents

- Introduction

- Cutting the Fabrics

- Ironing the Fabrics

- Embroidery Process

- Sewing the Masks

- Sewing the Lining

- Sewing the Hems

- Attaching the Lining to the Fabric

- Packaging Process

- Conclusion

Introduction

In today's video, I will be showcasing the process of creating masks in bulk. With the increasing demand for masks, I wanted to give you a behind-the-scenes look at how I create and package these products. In this article, I will guide you through each step of the process, from cutting the fabrics to sewing and packaging the masks. Join me as I take you on this in-depth journey and share valuable insights into the mask-making process.

1. Cutting the Fabrics

To start the mask-making process, I begin by cutting the fabrics in the required sizes. I have a list that helps me keep track of the quantity, color, and size of the masks I need to cut. By cutting all the fabrics at once, I can maximize productivity. For this particular video, I aim to make a hundred masks, meaning I need to cut 400 fabric pieces. This bulk cutting method allows me to streamline the production process efficiently.

2. Ironing the Fabrics

After cutting the fabrics, I then proceed to iron them. I sort them based on thickness, with the lining fabrics being thinner than the outer fabrics. Ironing the fabrics together helps eliminate any wrinkles or creases, ensuring a smooth sewing process. By taking the time to iron the fabrics at this stage, I can ensure ease and consistency in the subsequent sewing steps.

3. Embroidery Process

Next comes the embroidery process, where I add intricate designs to the masks. Using a sewing machine, I implement the desired designs onto the fabrics. This step involves changing threads for different colors and designs. I showcase a variety of embroidered masks in a time-lapse, providing a mesmerizing visual of the machine at work. The embroidery adds a personalized touch to each mask, making them unique and appealing.

4. Sewing the Masks

With the fabrics prepared, it's time to sew the masks. I group the fabrics based on color to optimize the sewing process. This allows me to minimize the thread change on the sewing machine, saving time and effort. Starting with the individual fabrics, I sew them together to create the outer layers of the masks. Then, I sew the lining fabrics together separately. Once all the pieces are ready, I proceed to sew them together to complete the masks.

5. Sewing the Lining

After sewing the outer masks, I focus on sewing the lining pieces. Grouped by color and size, I sew the lining fabrics in bulk. This approach ensures consistent quality and saves time. Sewing the lining is an essential step as it adds comfort and functionality to the masks.

6. Sewing the Hems

To prevent the fabrics from fraying, I sew the hems of the lining fabrics. This adds durability to the masks and ensures they maintain their shape. Sewing the hems is a crucial step in the production process, as it contributes to the overall quality and longevity of the masks.

7. Attaching the Lining to the Fabric

Once the hems are in place, I attach one piece of lining to one piece of fabric inside out. Sewing them together and flipping them inside out creates a neat and polished look. This step brings together the outer fabric and the lining, resulting in a well-constructed mask.

8. Packaging Process

After completing the sewing process, it's time to move on to packaging the masks. I have a dedicated packaging station where I lay out all the orders. Each order consists of an envelope with the customer's name, a thank you note, and a special discount code. I carefully package the masks and prepare them for shipment, ensuring that they are protected and ready to be delivered to their respective destinations.

9. Conclusion

In conclusion, creating masks in bulk requires meticulous planning and execution. From cutting the fabrics to embroidering and sewing, each step plays a crucial role in producing high-quality masks. By showcasing the behind-the-scenes process, I hope to give you a deeper appreciation for the effort and attention to detail that goes into creating these essential items. If you have any suggestions for future mask designs or any specific types of masks you would like to see, please leave a comment below. Thank you for joining me on this mask-making journey, and I hope to see you again soon!

Highlights

- Efficiently cutting fabrics in bulk to maximize productivity

- Ironing fabrics to ensure a smooth sewing process

- Adding intricate designs through embroidery for a personalized touch

- Sewing masks in an organized and systematic manner

- Securing the lining for added comfort and functionality

- Sewing hems to prevent fraying and maintain shape

- Attaching the lining to the fabric for a well-constructed mask

- Thoughtful packaging process for customer satisfaction

- Deep appreciation for the effort and attention to detail in mask-making

- Welcoming suggestions for future mask designs and types

FAQ

Q: How many masks can be made in one go?

A: By cutting fabrics in bulk and sewing them efficiently, it is possible to make a significant number of masks in one go. However, it is essential to ensure accuracy and attention to detail.

Q: Can the masks be customized with different designs?

A: Yes, the masks can be customized with different designs. Through embroidery, various designs and patterns can be added to create unique and personalized masks.

Q: Are the masks comfortable to wear?

A: Yes, the masks are designed with comfort in mind. The lining and careful construction ensure that the masks are comfortable to wear for extended periods.

Q: Can international orders be accommodated?

A: Yes, international orders are accepted and processed. Special care is taken to ensure that the masks are packaged securely for international shipping.

Q: Is there a discount available for future purchases?

A: Yes, customers receive a special discount code with their order, which can be used for future purchases. This discount is a token of appreciation for their support and loyalty.

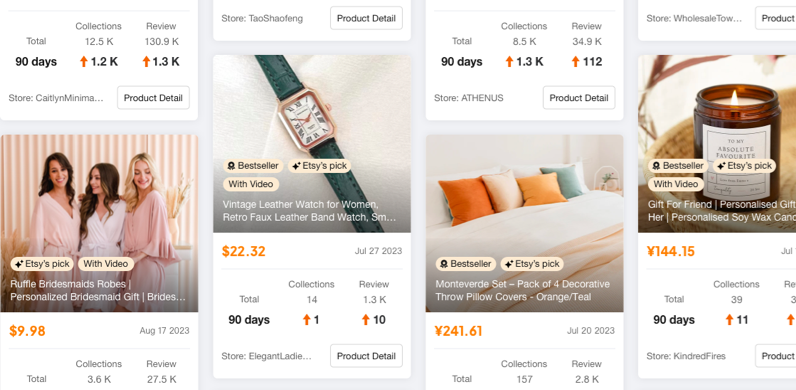

WHY YOU SHOULD CHOOSE Etsyshop

WHY YOU SHOULD CHOOSE Etsyshop