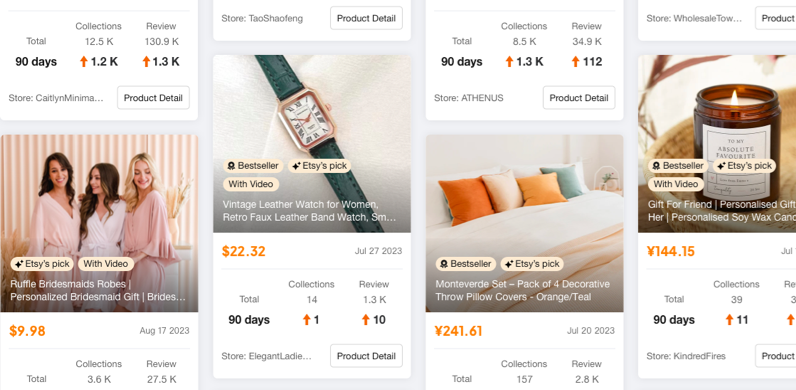

Discover the Hottest Etsy Products that Sell like Crazy!

Table of Contents:

- Introduction

- Preparing the Legs

2.1 Cutting the Legs to Rough Length

2.2 Using a Colored Pencil for Visibility

- Cutting the Tabletop Pieces and Aprons

3.1 Measuring the Rough Length

3.2 Using a Circular Saw and Speed Square

- Trimming the Boards for the Tabletop

4.1 Making a Pass for a Flat and Smooth Edge

4.2 Using Dowels for Alignment during Glue-up

- Optional Step: Adding Call Boards to Keep the Tabletop Flat

- Filling Dowel Holes with Glue and Placing the Dowels

- Cutting the Pieces for the Apron

7.1 Cutting the Short and Long Aprons

7.2 Adjusting the Table Saw for Square Legs

- Cutting the Legs to Final Length

8.1 Adding a Taper for Flair

8.2 Using a Tapering Jig for Consistency

- Routing a Profile along the Bottom of the Legs

- Pocket Hole Joinery for the Aprons

10.1 Adjusting the Pocket Hole Jig for 3/4" Stock

10.2 Marking and Drilling the Pocket Holes

- Sanding, Leveling, and Filling Gaps on the Tabletop

- Ripping the Tabletop to Final Width

- Cross Cutting the Tabletop to Final Length

- Adding an Edge Profile to the Tabletop

- Assembling the Base

15.1 Using a Scrap Piece of Plywood for Recess

15.2 Gluing, Clamping, and Screwing the Aprons

- Attaching the Tabletop to the Base with Walnut Buttons

16.1 Routing Slots for the Buttons

- Applying the Finish

- Final Assembly and Delivery

- Conclusion

Building a Custom Wood Table: Step-by-Step Guide

Introduction

Building a custom wood table allows you to create a unique, personalized piece of furniture that adds character to your home. In this step-by-step guide, we will walk you through the process of building a custom wood table, from preparing the legs to the final assembly. By following these instructions, you will be able to create a beautiful and functional table that will enhance your living space.

- Preparing the Legs

Before you can start building the table, you need to prepare the legs. This involves cutting them to the desired length and ensuring visibility with the use of a colored pencil to make accurate marks.

- Cutting the Tabletop Pieces and Aprons

Next, you will need to cut the tabletop pieces and aprons to the rough length. By using a circular saw and a speed square, you can achieve precise cuts.

- Trimming the Boards for the Tabletop

To make the boards for the tabletop flat and smooth, it is important to make a pass on the rough edge. This will ensure a perfect alignment during the glue-up process.

- Using Dowels for Alignment during Glue-up

To maintain the flatness of the tabletop during the glue-up, dowels can be used for alignment. This step is optional but highly recommended for better results.

- Optional Step: Adding Call Boards to Keep the Tabletop Flat

To prevent glue from sticking to the boards during the glue-up process, call boards covered in clear packing tape can be used. This will help keep the tabletop flat and free from any unwanted glue residue.

- Filling Dowel Holes with Glue and Placing the Dowels

After drilling dowel holes, fill them with glue and place the dowels. This will provide additional strength and stability to the tabletop once it is assembled.

- Cutting the Pieces for the Apron

The aprons play a crucial role in supporting the tabletop. By cutting the short and long aprons at the same time, you can ensure identical widths.

- Cutting the Legs to Final Length

To achieve square legs, use a table saw to cut the leg stock to the final length. Adjust the fence of the table saw to match the thickness of the stock for accurate cuts.

- Adding a Taper for Flair

To add a touch of flair to the legs, mark where the taper will begin and end on each leg. This can create a visually interesting effect for the finished table.

- Routing a Profile along the Bottom of the Legs

By using a small chamfer bit in a cordless router, you can create a profile along the bottom of each leg. This will prevent wood splitting and add a subtle shadow when the table is moved.

- Pocket Hole Joinery for the Aprons

To attach the aprons securely to the legs, pocket hole joinery can be used. Adjust the pocket hole jig and drill the necessary holes for a sturdy and stable connection.

- Sanding, Leveling, and Filling Gaps on the Tabletop

Once the tabletop is dry, sand it down to level any uneven spots. Fill any hairline gaps with a mixture of glue and sawdust for a seamless finish.

- Ripping the Tabletop to Final Width

Using a table saw, rip the tabletop to its final width. This ensures that both sides are parallel and the tabletop is of uniform size.

- Adding an Edge Profile to the Tabletop

To give the tabletop a finished look, use a router with a roman og bit to create an edge profile. Start with the end grain and gradually work along the long edge for the best results.

- Assembling the Base

Assemble the base by gluing, clamping, and screwing the aprons to the legs. Use quarter-inch plywood as a recess for the aprons to create a visually appealing design.

- Attaching the Tabletop to the Base with Walnut Buttons

Attach the tabletop to the base using walnut buttons. These buttons allow for the expansion and contraction of the solid wood tabletop, ensuring its long-term stability.

- Applying the Finish

Apply the finish of your choice to protect and enhance the beauty of the wood. This step will bring out the character of the table and provide a durable surface.

- Final Assembly and Delivery

Once the finish is dry, assemble the base and tabletop using the walnut buttons. Ensure a secure attachment for a stable and long-lasting table. Finally, deliver the completed table to its intended location.

- Conclusion

Building a custom wood table is a rewarding and fulfilling project that allows you to express your creativity and craftsmanship. By following these step-by-step instructions, you can create a beautiful and functional table that will be a centerpiece in your home for years to come.

Highlights:

- Creating a custom wood table from start to finish

- Utilizing tools such as a circular saw, speed square, and table saw

- Incorporating dowels for alignment and pocket hole joinery for stability

- Adding personal flair with tapers and router profiles

- Applying finishes for protection and aesthetics

- Building a strong and durable table with precise measurements and techniques

- Crafting a unique piece of furniture to enhance your living space

FAQ:

Q: Can I use different types of wood for this project?

A: Yes, you can use different types of wood based on your preference and availability. Just ensure that the wood is suitable for furniture-making and can withstand the desired finish.

Q: Do I need advanced woodworking skills to build this table?

A: While some basic woodworking skills are recommended, this project can be tackled by enthusiasts at various skill levels. Following the step-by-step instructions and utilizing the right tools will help you achieve a successful outcome.

Q: Can I customize the dimensions of the table?

A: Yes, you can customize the dimensions of the table to fit your specific needs. However, it is important to maintain proportional measurements and sturdy construction for stability.

Q: What type of finish do you recommend for the table?

A: The choice of finish depends on personal preference and the desired look for the table. Common options include oil-based finishes, polyurethane, or wax. Consider factors such as durability, ease of application, and the desired level of sheen when selecting a finish.

WHY YOU SHOULD CHOOSE Etsyshop

WHY YOU SHOULD CHOOSE Etsyshop