Stunning 3D CNC Carved Artwork - Unique Etsy Find

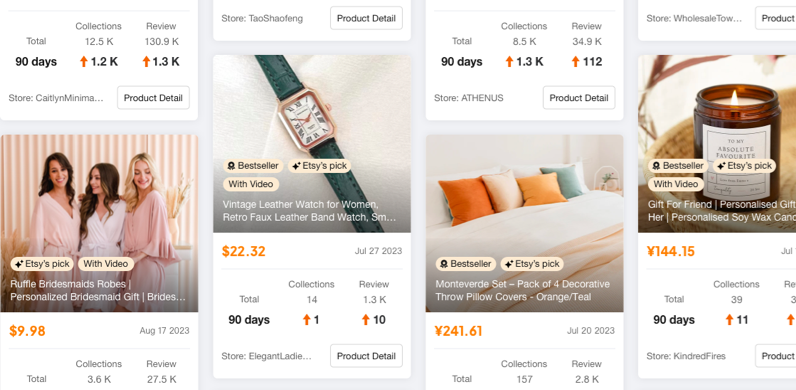

I am a ETSY merchant, I am opening several ETSY stores. I use Etsyshop to find ETSY stores and track competitor stores. Etsyshop really helped me a lot, I also subscribe to Etsyshop's service, I hope more people can like Etsyshop! — Ecomvy

Join Etsyshop to find the ETSY store & products

To make it happen in 3 seconds.

Sign Up

- App rating

- 4.9

- ETSY Store

- 2M+

- Trusted Customers

- 1000+

- No complicated

-

- No difficulty

-

- Free trial

-

Browse More Content

Etsy Seller

- Unveiling the Dark Secret of the Etsy Algorithm

- Level up your style with trendy sleeve prints from Etsy + Printify

- Etsy Prep: Best Pricing Tips for Plushie Drop 2023

- Making Passive Income with Digital Scrapbook Elements

- Easily Adding Videos to Etsy Listings Using an iPhone

- Create & Sell Digital Downloads on Etsy with Canva

- Unveiling the Dark Side of Etsy: #KeepEtsyHuman

- Skyrocket Your Etsy Sales with This TikTok Hack

- Earn $3000/mo with Etsy Selling Squarespace Templates

- Create and Sell Digital Paper for Etsy

Etsy Seo

- Unlocking Etsy Success with Google SGE

- Mastering E-Commerce SEO: Your Path to Success

- Unveiling Etsy's SEO Changes in 2023

- Boost Your Etsy SEO: Common Mistakes to Avoid

- Unlock Etsy Success: Strategies for Finding Unsaturated Niches

- Mastering SEO Writing for Online Success

- Mastering Etsy SEO: Boost Sales & Visibility

- Unlock Etsy SEO 2023: Top Digital Products & Keywords

- Maximizing Marmalade for Etsy SEO Success

- Boost Your Etsy SEO in 2023

Etsy Dropshipping

- Master the Art of Selling Posters on Etsy

- Dropshipping Success: $31,271 in 1 Month!

- Streamline Multi-Channel Sales with Nimble Web

- How I Made $45k in 2 Months on Etsy - A Case Study

- The Ultimate Guide to Succeed in Etsy Drop Shipping

- Etsy vs. Shopify: Crafting Your E-Commerce Success

- Etsy vs Shopify: Which Platform is Right for You?

- Dominate the Wedding Jewelry and Accessories Market on Etsy

- Etsy vs Shopify: Making the Right Choice for Your Online Business

- Etsy vs. Shopify: Choose Your E-commerce Path

To sell on etsy

- Inside the Trendiest Etsy Shop: Office Tour and Product Sneak Peek!

- Unveiling the Secrets of Etsy's Top Seller: 2 MILLION Sales Revealed

- Boost Your Etsy Sales with Easy SEO Tricks!

- Discover Trendy Products from ETSY, Target, & Amazon!

- Top Craft Business Ideas for Sublimation Printing in 2023

- Hottest Etsy Trends for Summer and Autumn 2023

- Unleash the Power of Etsy: Earn $42,000 in 30 Days Selling T-Shirts!

- Behind the Scenes of a Successful Etsy Jewelry Business

- Unveiling Etsy's Untapped Market Potential

- Discover Stunning Fantasy & SciFi Miniatures from a Trustworthy Etsy Seller