Revolutionary Milwaukee Packout Hack

Browse More Content

Etsy shop

- Discover Untapped Print on Demand Products with ChatGPT4

- Unleashing Etsy's Unstoppable Growth

- Profitable Hand Towel Embroidery: Etsy Selling Guide!

- New Holiday Cards and Author Portraits on Etsy!

- ETSY STAR SELLER Secrets Revealed

- Exciting Update: My First Plushie Arrived! - Business Vlog

- Unbridled Etsy Battles: KingCobraJFS vs the World

- Unboxing Beautiful Orchids from Etsy's Triton Orchids

- Empowering Women in Tech: Etsy's Remarkable 500% Growth in Female Engineers

- Maximizing Profit: Etsy vs Poshmark

Etsy Seo

- Unlocking Etsy Success with Google SGE

- Mastering E-Commerce SEO: Your Path to Success

- Unveiling Etsy's SEO Changes in 2023

- Boost Your Etsy SEO: Common Mistakes to Avoid

- Unlock Etsy Success: Strategies for Finding Unsaturated Niches

- Mastering SEO Writing for Online Success

- Mastering Etsy SEO: Boost Sales & Visibility

- Unlock Etsy SEO 2023: Top Digital Products & Keywords

- Maximizing Marmalade for Etsy SEO Success

- Boost Your Etsy SEO in 2023

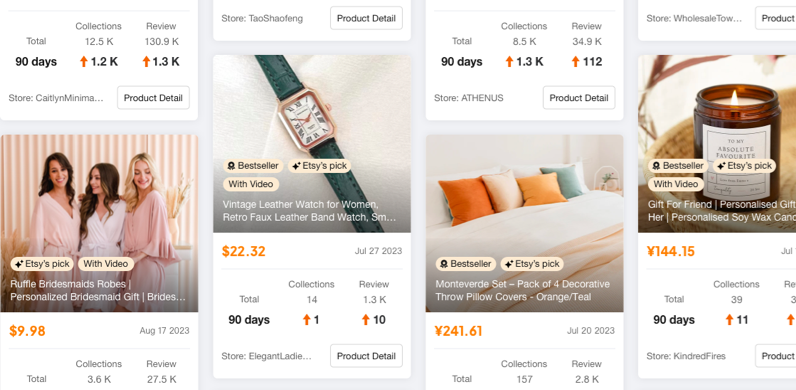

Etsy Dropshipping

- Master the Art of Selling Posters on Etsy

- Dropshipping Success: $31,271 in 1 Month!

- Streamline Multi-Channel Sales with Nimble Web

- How I Made $45k in 2 Months on Etsy - A Case Study

- The Ultimate Guide to Succeed in Etsy Drop Shipping

- Etsy vs. Shopify: Crafting Your E-Commerce Success

- Etsy vs Shopify: Which Platform is Right for You?

- Dominate the Wedding Jewelry and Accessories Market on Etsy

- Etsy vs Shopify: Making the Right Choice for Your Online Business

- Etsy vs. Shopify: Choose Your E-commerce Path

To sell on etsy

- Hottest Etsy Trends for Summer and Autumn 2023

- Unleash the Power of Etsy: Earn $42,000 in 30 Days Selling T-Shirts!

- Behind the Scenes of a Successful Etsy Jewelry Business

- Unveiling Etsy's Untapped Market Potential

- Discover Stunning Fantasy & SciFi Miniatures from a Trustworthy Etsy Seller

- Creative Crafts from Scraps: Etsy's Hottest Sellers!

- Unleash Your Imagination with High-Quality Etsy Miniatures for D&D

- Get Crafty with DIY Stickers for Your Planner!

- Behind the Scenes of a Busy Etsy Shop! Join me as I Process Orders and Ship Packages!

- Unveiling the Secrets of Selling AI Digital Tumbler Wraps & Making $500+ Daily on Etsy